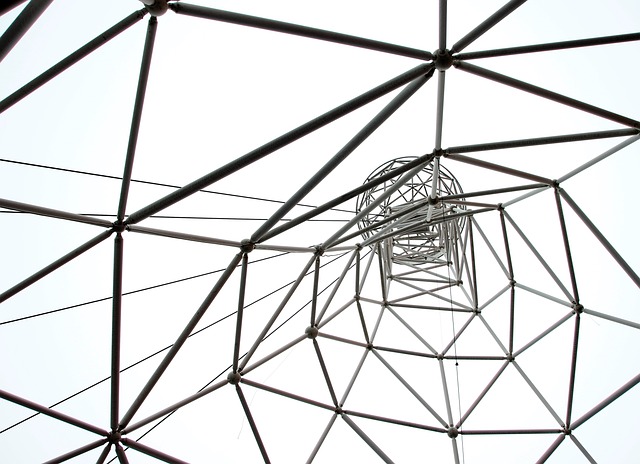

Scaffold towers are indispensable tools in construction and maintenance work, providing workers with safe and efficient access to elevated areas. However, working with scaffold towers can pose significant risks if proper safety precautions are not followed. In this article, we will discuss ten essential safety tips to ensure the well-being of workers when using scaffold towers. By adhering to these scaffold tower safety guidelines, you can minimize accidents and create a secure working environment.

1. Proper Training and Certification

Before working with scaffold towers, it is crucial to receive comprehensive training from a qualified instructor. This training should cover assembly, dismantling, and safe usage techniques specific to scaffold towers. Additionally, ensure that you and your colleagues are certified to operate the equipment, as this will help prevent potential accidents caused by inadequate knowledge.

2. Inspect the Scaffold Tower

Perform a thorough inspection of the scaffold tower before each use. Check for any loose or damaged components, such as guardrails, platforms, and braces. Ensure that all parts are in good working condition and that there are no signs of corrosion or structural weaknesses. Report any issues to the appropriate personnel for immediate repairs or replacements.

3. Follow Assembly Guidelines

Proper assembly is critical for the stability and safety of scaffold towers. Always follow the manufacturer’s instructions and guidelines meticulously during assembly. Ensure that all components are securely connected, and the tower is plumb and level. Never take shortcuts or use makeshift repairs, as they compromise the integrity of the structure and increase the risk of accidents.

4. Use Stabilizers and Braces

Stabilizers and braces are essential components of scaffold towers that enhance stability. Install these devices according to the manufacturer’s instructions, and make sure they are secure and fully engaged. Stabilizers help distribute the load and prevent tipping, while braces provide lateral support. By utilizing these components correctly, you can significantly reduce the risk of scaffold tower instability.

5. Secure the Scaffold Tower

Once the scaffold tower is assembled, it must be properly secured to prevent movement or collapse. Use adequate tie-ins, such as ropes or braces, to anchor the tower to a sturdy structure. Follow the manufacturer’s recommendations for securing methods and ensure that all connections are tight. Regularly inspect and tighten tie-ins to maintain the tower’s stability during use.

6. Maintain Clear Access and Egress

To promote safe movement on scaffold towers, it is essential to maintain clear access and egress points. Ensure that ladders or stair towers are securely attached, and all guardrails and toe boards are in place. Avoid placing materials or tools on access points that could impede entry or exit. Clear paths contribute to quick and safe evacuation in case of emergencies.

7. Use Personal Protective Equipment (PPE)

Wearing appropriate personal protective equipment is crucial for safeguarding against potential hazards. When working with scaffold towers, always wear a hard hat, a high-visibility vest, and non-slip footwear. Additionally, use safety harnesses and lanyards when working at heights. PPE should be regularly inspected for damage and replaced as necessary.

8. Be Mindful of Weather Conditions

Weather conditions can significantly impact the safety of scaffold tower operations. Avoid working on scaffold towers during adverse weather conditions such as high winds, storms, or icy surfaces. Windy conditions can destabilize the tower, while slippery surfaces increase the risk of falls. Continuously monitor weather forecasts and suspend work when conditions become hazardous.

9. Practice Safe Load Management

Scaffold towers have load limits that should never be exceeded. Before starting any work, determine the maximum load capacity and distribute the weight evenly across the platforms. Avoid overloading with excessive materials or tools that could strain the tower’s structure. Proper load management ensures the stability and integrity of the scaffold tower.

10. Regular Inspections and Maintenance

Regular inspections and maintenance are vital to ensure the ongoing safety of scaffold towers. Establish a schedule for routine inspections and conduct them thoroughly. Check for signs of wear and tear, such as rust, cracks, or bent components. Inspect the locking mechanisms, wheels, and all movable parts to ensure they are in proper working condition. Additionally, conduct load testing periodically to verify the tower’s stability and weight-bearing capacity. Any defects or issues discovered during inspections should be reported immediately for prompt repairs or replacements.

Conclusion

Working with scaffold towers can be hazardous if proper safety measures are not followed. By implementing these ten essential safety tips, you can create a secure working environment and minimize the risk of accidents. Remember to prioritize training and certification, conduct thorough inspections, adhere to assembly guidelines, and use stabilizers and braces for stability. Secure the tower properly, maintain clear access and egress, and always wear appropriate PPE. Consider weather conditions, practice safe load management, and perform regular inspections and maintenance. By prioritizing safety, you can ensure a productive and accident-free work environment when using scaffold towers.